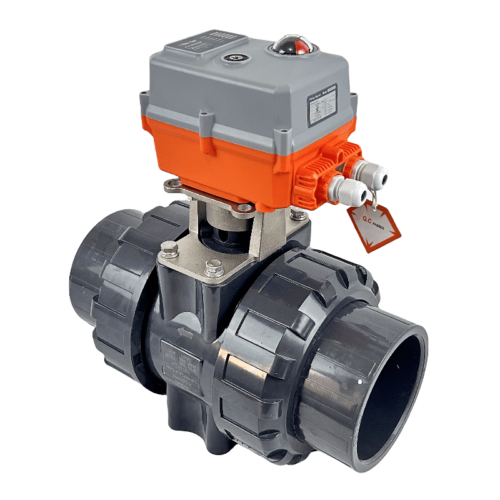

UPVC Safety Valve/Back Pressure Valve

The diaphragm and valve core are pressed against the valve seat by an internal spring. When the pressure in the system piping exceeds the preset pressure, the diaphragm and valve core are lifted, allowing the medium to leak into the return line and container. The adjusting screw is field adjustable. Use the pressure gauge in the pipeline to set the pressure within the range of 0 to 1.0 MPa. The relief pressure is typically set 0.1 to 0.2 MPa above the system pressure. The pressure adjustment of the safety valve must not exceed the maximum pressure of the pump.

The safety valve is typically installed as close to the pump outlet as possible. No valves should be installed between the pump and the safety valve to protect the pump and ensure proper system operation.

The back pressure valve is installed in the positive pressure discharge line of a metering pump or diaphragm pump to prevent siphonage and eliminate variations in the maximum dosing rate caused by pressure fluctuations at the dosing point, thereby ensuring pump dosing accuracy. Remove the protective cap from the adjusting screw, turn the adjusting screw, and adjust to the desired pressure using the pressure gauge in the pipeline.

The back pressure can be set within a range of 0 to 0.6 MPa using the adjusting screw. Used in conjunction with a pulse dampener, it reduces system damage caused by water hammer, maintains a constant pressure between the pump outlet and the back-pressure valve, and maintains a constant system flow.

Technical Parameters

Material: UPVC, PP, CPVC, PVDF, SUS304, SUS316L;

Working pressure: 0~1.0MPa, 02~16MPa

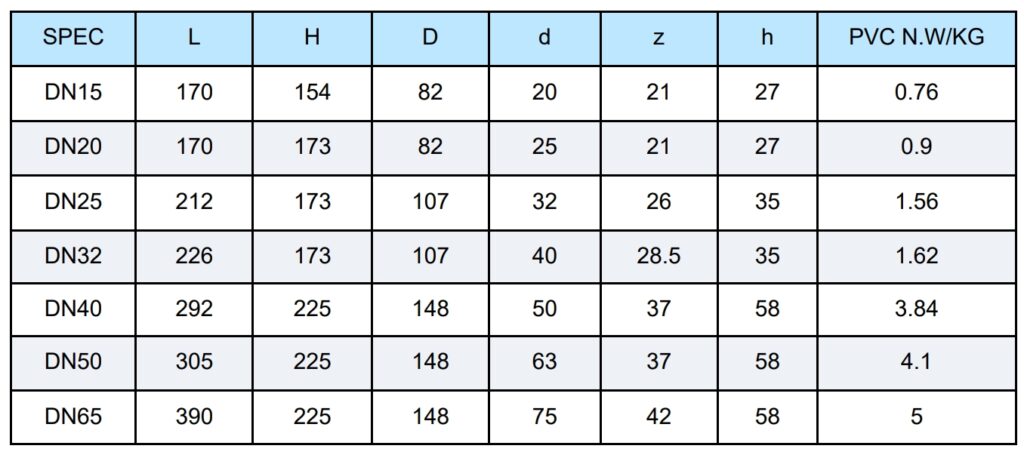

Caliber size: DN15, DN20, DN25, DN32, DN40, DN50, DN65;

Connection method: bonding, hot melt welding, thread,flange;

Diaphragm material: PTFE+rubber composite

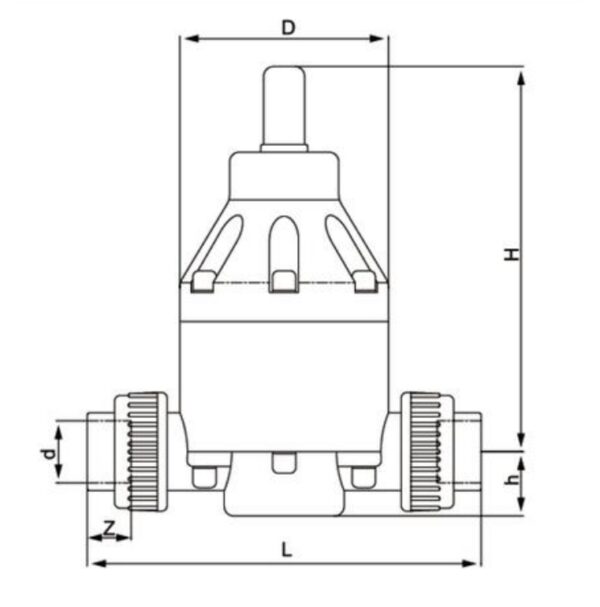

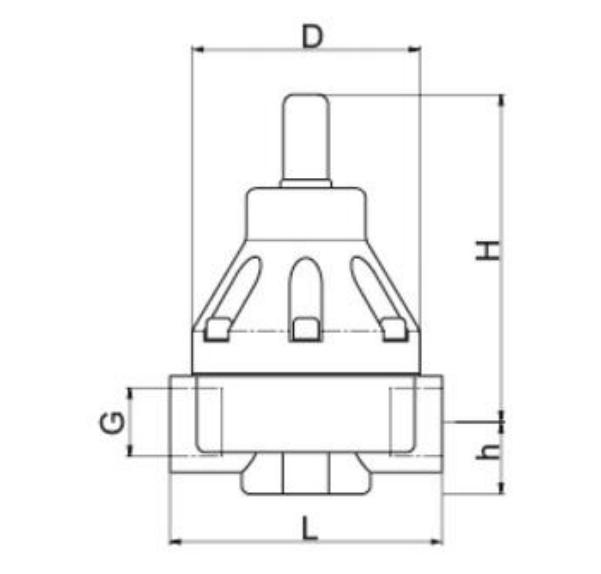

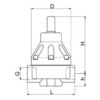

Dimensions