| Pressure reducing valve installation and maintenance instructions |

| Installation and Usage Instructions |

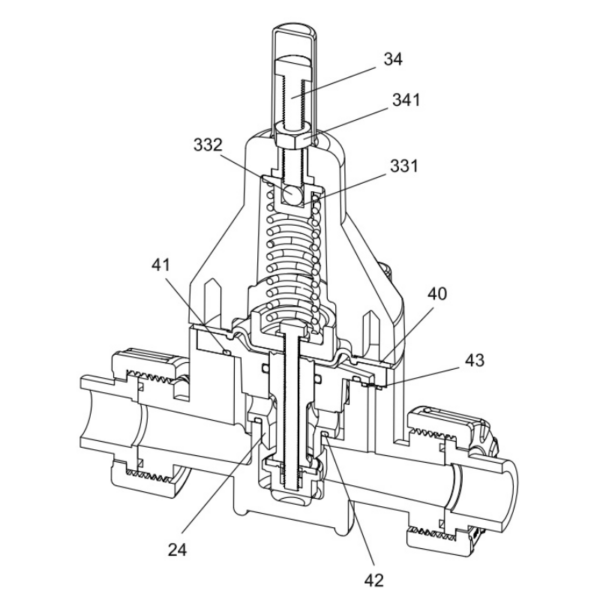

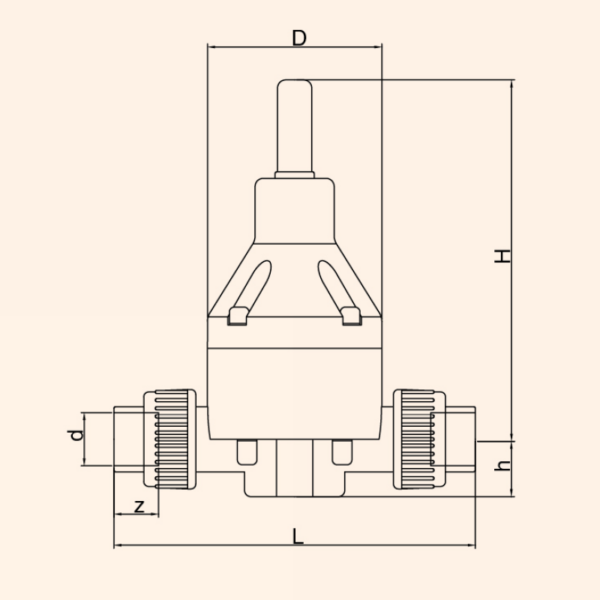

Valve body parameters |

| Install |

Flow direction should be consistent with the arrow direction on the valve body. |

Body material |

UPVC、CPVC、PP |

| Check valve body pressure |

Use a neutral medium to check the pressure, such as water. |

Diameter |

DN15~DN50 |

| Test pressure < permissible equipment pressure. |

Pressure |

1.0Mpa |

| Test pressure < 1.5PN. |

Diaphragm material |

PTFE+Composite rubber |

| Test pressure < PN + 5 bar to check valve seal. |

Connection method |

Adhesive bonding, Hot melt bonding, Thread, Flange |

| Set pressure |

Factory default value: 1 bar (other default values can be agreed upon with the manufacturer). |

Output pressure |

1~9bar |

| The pressure relief valve must be set according to the environmental conditions that will be used in the future. |

Maintenance and Repair |

| Recommended setup: Install a diaphragm pressure gauge at the front end of the pressure reducing valve. |

Maintenance |

The normal operating condition remains unchanged, and the sealing performance is normal. |

| Step: |

Operating noise and vibration; |

| 1. Remove the protective cover of the adjusting bolt and loosen the bottom locking nut. |

Tighten the housing bolts to the specified torque, and clean the valve with a damp cloth as needed. |

| 2. Rotate the adjusting bolt counterclockwise until you can clearly feel the compression spring completely released. |

Repair |

Protective equipment should be properly installed as required, media should be safely recycled, and hazardous waste should be disposed of in an environmentally friendly manner. |

| 3. Start the equipment and rotate the adjusting bolt clockwise until the desired equipment pressure is reached. |

Remove the valves to ensure the equipment is emptied, depressurized, and cooled. |

| 4. Use a box wrench to hold the adjusting bolt in place while tightening the lock nut, then install the protective cover. |

Ensure the equipment will not restart, then remove the valve from the pipeline. |

| 5. If necessary, the adjusting bolts can be sealed with lead to prevent unauthorized adjustments. |

When it is necessary to disassemble a valve, be aware that there may still be media in the dead corners of the valve. |