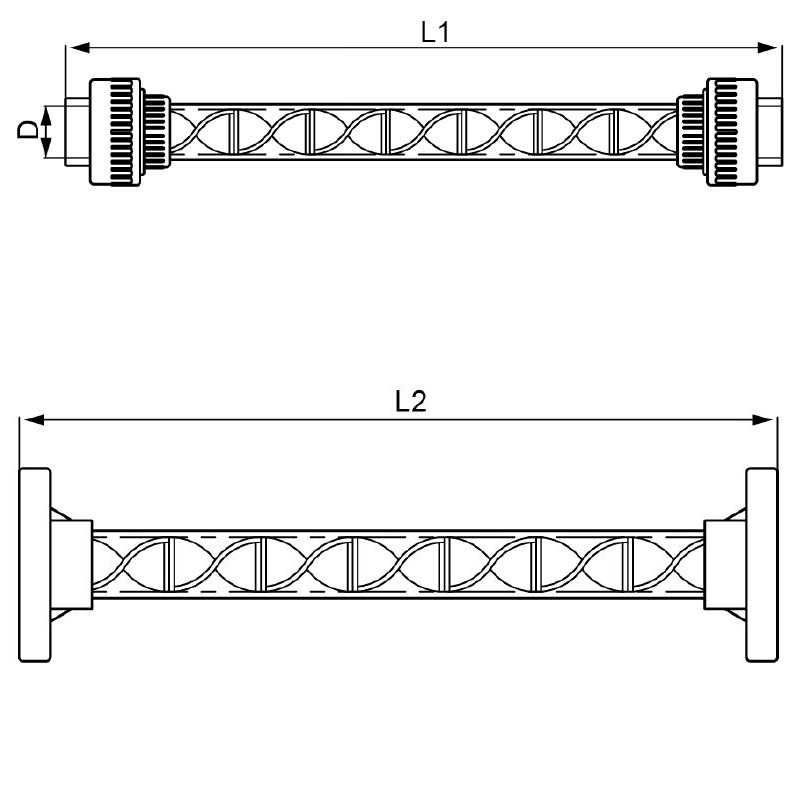

Pipeline mixers, also known as static mixers, are ideal devices for achieving instantaneous mixing of various chemicals and water. They are highly effective for adding various coagulants, flocculants, ozone, liquid chlorine, and in acid-base neutralization and gas-water mixing systems. The product features rapid and efficient mixing, simple structure, energy saving, and compact size. Without external force, water flows through 6-8 mixing units, which cross-flow and split, while vortices rotate in opposite directions and continuously cross-flow, achieving excellent mixing results instantly with a mixing efficiency of 90-95%.

Materials: UPVC, PP, CPVC, PVDF. The various chemicals should be added at least 25cm from the front end of the pipeline mixer. Using it in conjunction with an ejector will yield better results.

The pipeline for adding chemicals should be designed according to water supply and drainage standards. The flow velocity inside the pipe should be greater than 0.9m/s, and the internal pressure should be less than 1.6MPa.

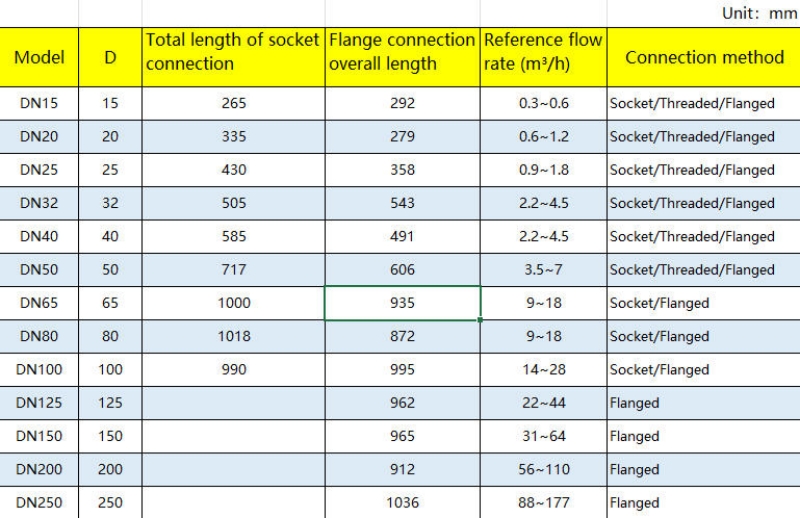

Pipeline mixers are designed for specific diameters and flow rates. When the flow rate decreases, the head loss drops significantly, noticeably affecting the mixing effect.