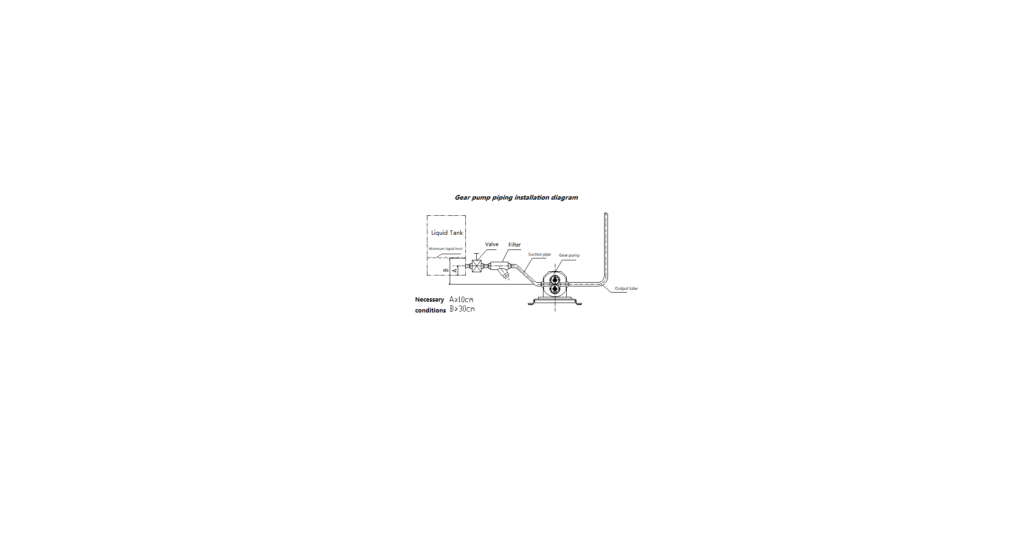

① Install the gear metering pump as close to the liquid tank as possible. Due to the limited self-priming capacity of the gear metering pump, the inlet of the gear metering pump should be at least 30 cm below the liquid level during installation.

② Where impurities may enter, the suction pipe must be 10 cm above the bottom of the liquid tank to prevent precipitated impurities from entering the pump chamber.

③ Install the filter close to the liquid tank. Choose a filter with an appropriate design and mesh size. It should be safe and effective, but not too dense to cause excessive suction resistance or even blockage. It should also be easy to clean.

Note: The filter is directional; do not install it upside down! ④ The gear metering pump should be installed in a bright, dry, and clean location to facilitate maintenance and inspection. Space must also be reserved for disassembly and inspection. The installation surface must be clean and flat.

⑤ The gear metering pump is designed to have a fixed direction of rotation and does not allow reversal. Therefore, the material inlet and outlet must be clearly identified before installation. (The arrow on the gear metering pump’s nameplate indicates the material flow direction, from the inlet to the outlet.)

⑥ The diameter of the connecting pipe should be as large as possible, and should not be smaller than the inner diameter of the pipe joint. The suction pipe should be rigid or have a skeleton finish to prevent the inlet pipe from flattening due to excessive suction. The outlet pipe should have a sufficiently thick wall to withstand maximum pressure.

⑦ The interior of the pipe must be clean and free of any debris to prevent foreign matter from entering the gear metering pump and damaging internal components.

⑧ The pipe must not have raised bends or dead corners that could trap gas. Knots or tangles that could block the pipe are strictly prohibited. When installing the inlet and outlet pipes, be careful not to place weight on the gear metering pump, as this will affect its service life.

⑨ Pipe connections must be tight to prevent material and air leaks to ensure accurate delivery from the gear metering pump. After installation, check the pipe seals with air and soapy water.

Special Note: Be sure to wrap the valve, filter, and gear metering pump inlet and outlet connections with teflon tape and secure them with pipe clamps or wire to prevent air from entering the suction pipe, which could affect the pump’s flow rate and accuracy. In severe cases, the pump may not deliver material, leading to damage.